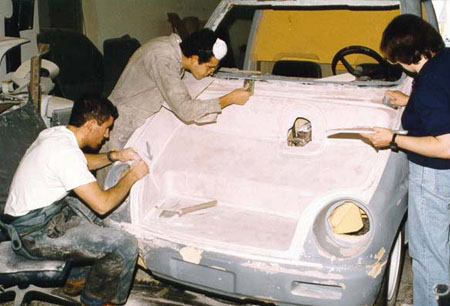

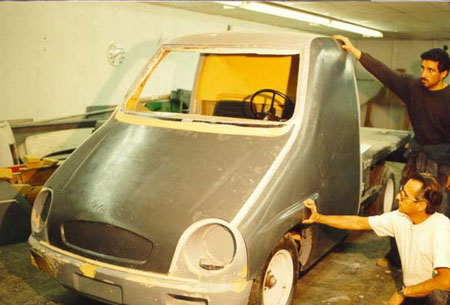

In 1996 Taylor Dunn hired the services of design consultants Aros-Throndson to redesing their largest vehicle, at that time the “Electruck”. Myself and two more colleagues students at CIDI, UNAM were offered an internship to help develop the prototype.

We first hand-made a 1:1 scale of the new design in rigid polyurethane foam reinforced with plastic filler (better known as Bondo), after that we casted moulds in fibreglass from that model in order to produce the final parts also in fibreglass. Later everything was assembled into the final prototype. All done under 3 months!

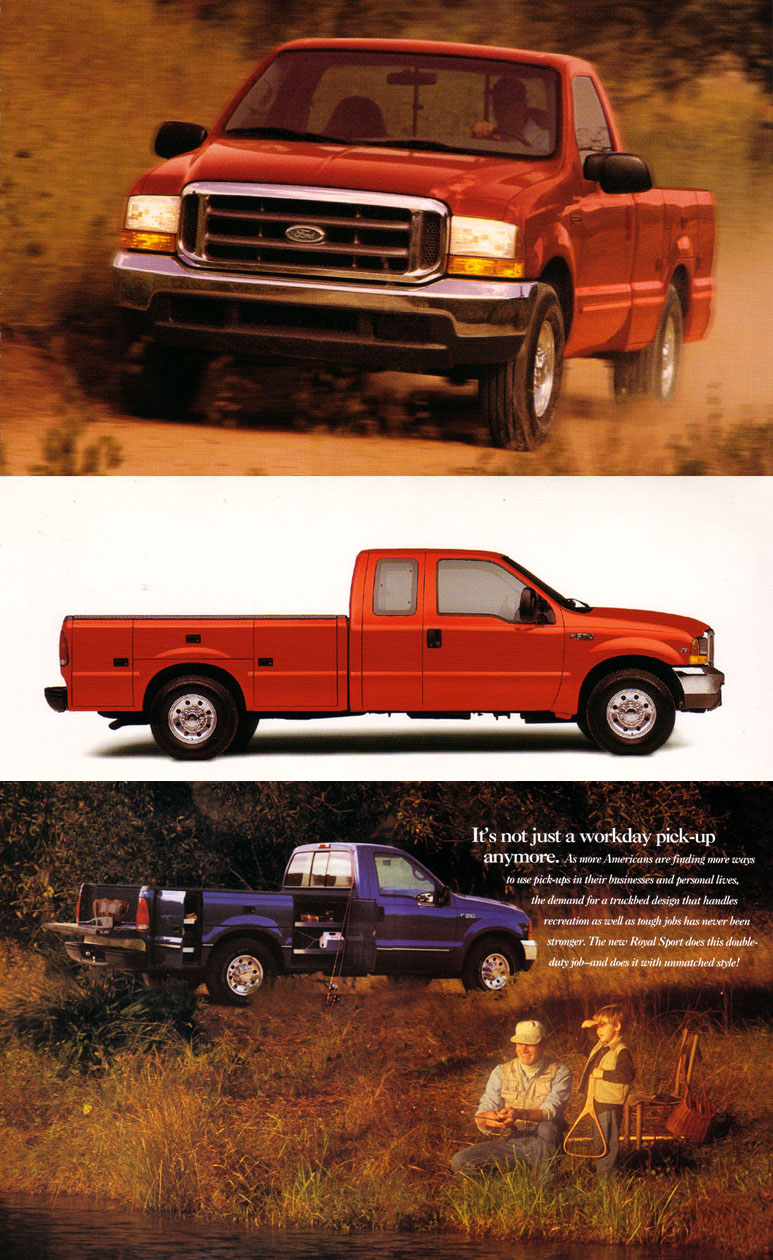

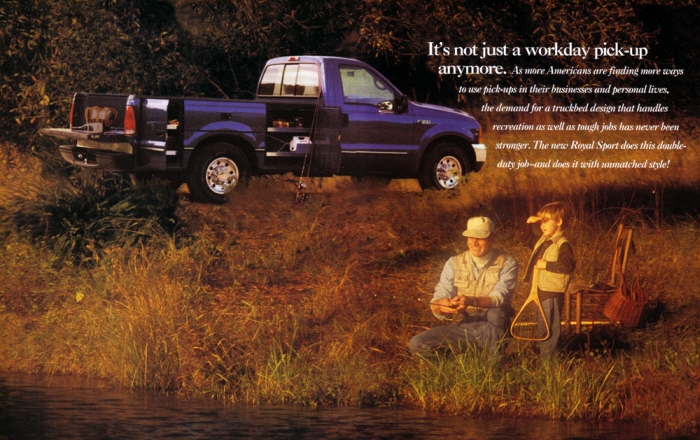

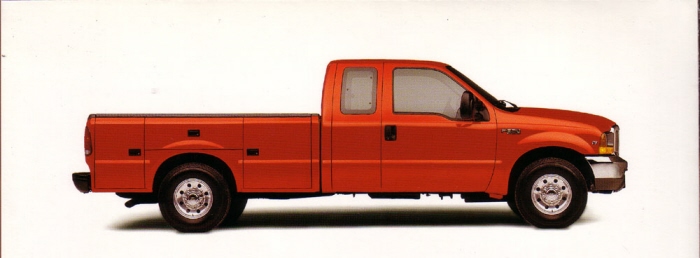

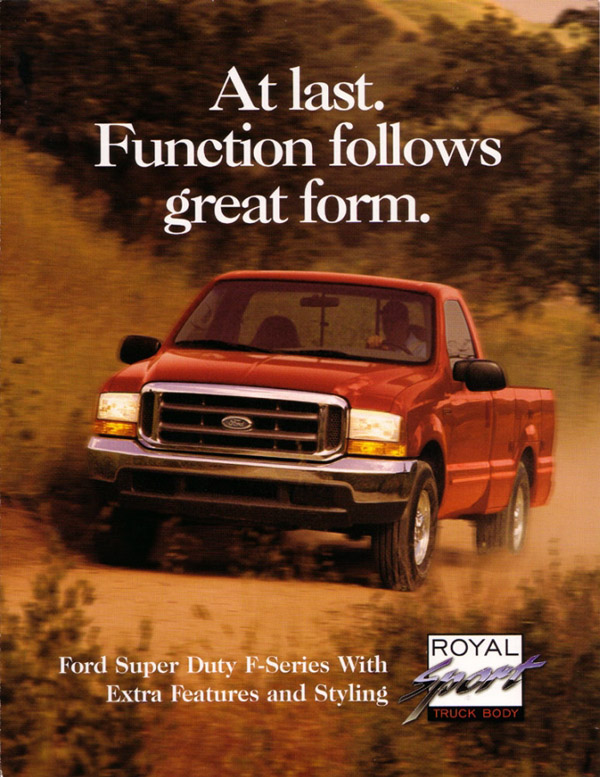

In 1998 Aros-Throndson offer me another internship, this time to work on a project for Royal Truck Body. We were to design and manufacture directly as a Ford product Utility Service Body vehicles. The main idea was to change the usually square and boring aesthetics of service body vehicles for an equally function-efficient version but following the aesthetics of Ford’s new “Super Duty” series.

We designed the entire body, built 6 prototypes which were used for demonstrations all over the country and together with an engineer help designed and set up the manufacturing line. We reduced the amount of parts by 70% and speed up the process from 2 hours to 15 minutes per body built. It was such a great success that after that experience Royal Truck Body got the same deal for GMC and Dodge.